Welting- and Stitching Awl

These tools are required for piercing the insole in order to sew the welt

and stitch the welt so as to attach the sole.

Shoemaker´s Hammer

The hammer has a mushroom-shaped face and a flat cross pane.

It is used for driving nails and for consolidating and shaping leather.

St. Hugh´s Bone

This tool is made from bone and boxwood.

It is used for shaping, smoothing, flattening and polishing.

Broken Pieces of Glass

The glass is scratched and cracked quickly.

The sharp and slightly rounded edge is used for

trimming and plaining edges and surfaces.

Inks and Elixirs

These are used for nourishing the leather and treating the surface.

Old recipes give the shoes a wonderful patina and make them durable.

Spirit Lamp with Edge Iron

With the lamp, different irons are heated to a certain

temperature to burn waxes in the sole and heel edges.

Waist Iron

This tool shapes the sole edge between forepart and the heel.

The appearance there is thinner and more elegant: The beveled waist.

Seat Wheel

Having been heated, the tool is run round the seat of the heel

in order to set the edge and at the same time to produce

decorative marking on the seat.

Shoe Pincer

The pincer is used for extracting

nails and to pinch off nail heads.

Lasting Pincer

Pincer and hammer in one tool. The upper(leather) is pulled

over the last and tacks are driven in to hold it in position.

Pegging Awl

Used for boring holes in the sole and heel

to take wooden pegs inserted as a means of attachment.

Wooden Pegs

They have pyramidal points and are driven

in the holes with one precise hammer blow.

Hemp and Flax thread

Hemp and flax fibers are used to make the hand sewing thread

in the desired thickness. Pitch and wax is rubbed in.

Pitch

Pitch is cooked wood resin and is also known as colophony.

With oil and tar it achieves the perfect consistency for sticking the

fibres together and making them durable.

Edge Irons and Burnishing Tools

The heated tools have the useful purpose of sealing the fibers against water and so preserving the shape and appearance of the bottom.

Address

Patrick Frei Maßschuhe

Ferdinand-Weiss-Str. 9–11

D-79106 Freiburg

Tel: +49 761 2177030

patrick@freischuhe.de

Opening Hours

Monday to Friday

9 a.m. - 1 p.m.

Afternoons und Saturdays

by appointment

Thanks

Eckart Schadt was the Creative Director of this site.

Andreas Berenz acted as programmer.

All photographs were taken by Andreas Lörcher.

World Champion in shoemaking

I am proud to have won the World Championships in shoemaking in London 2018

The shoe will be showcased at these locations:

May 7-20----------Leffot NY---New York, USA

May 28-June 10----Leffot Chicago---Chicago, USA

June 18-July1------Kevin Seah---Singapore

July 9-22----------Unipair---Seoul, South Korea

July 30-Aug 12----Medallion Shoes---Beijing, China

Aug 20-Sept 2----Prologue---Hong Kong

Sept 10-23--------Skoaktiebolaget---Stockholm, Sweden

October 1-14------Isetan Men’s---Tokyo, Japan

Oct 22-Nov 4-----Skomaker Dagestad---Oslo, Norway

Nov 12-25---------Brogue Shoes---Geneva, Switzerland

Workshop Impressions

On the next few pages you can take a look around in my workshop and get an impression of how I work.

After the pictures of the workshop you will find images taken from my antiquarian library. Clicking on “Antiquarian” will take you straight there.

Use the arrows in the frame to flick through. On touch screens, just swipe to proceed.

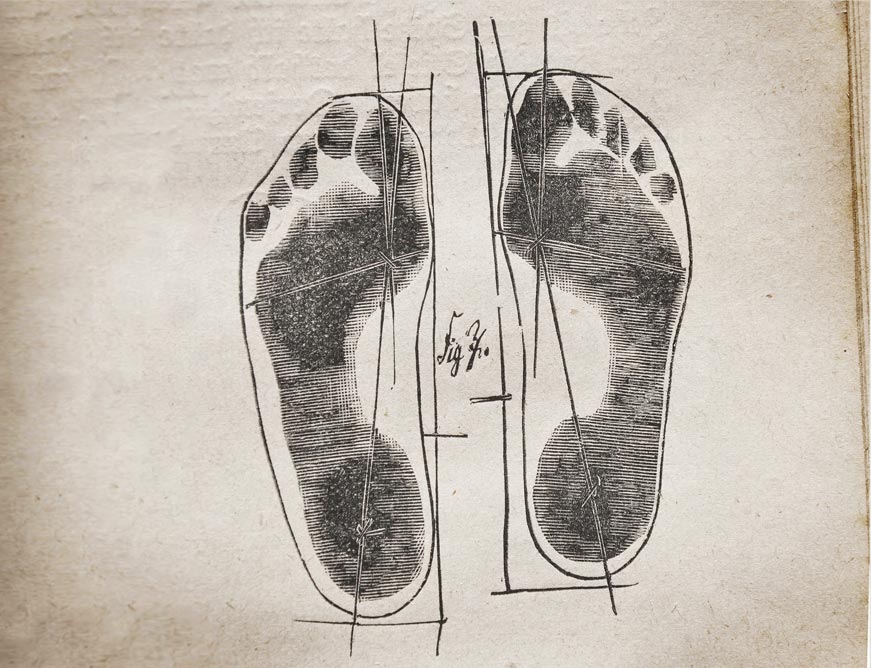

Three steps to the bespoke shoe

Anyone whose feet make their way into my workshop joins me in delving into the world of shoes. It is there that we develop an individual pair or even a personal collection. Footwear that fits its wearer perfectly, expresses his or her very own style, and envelops his or her feet as if the shoes were a second skin.

No fewer than three appointments with the customer are required for this. On the next few pages you can find out all about the process.

Use the arrows in the frame to flick through. On the touchscreens you can simply swipe to move on.

The shoemaker and his perspective

In my Freiburg workshop, I revive age-old knowledge of the art of shoemaking. Pure craftsmanship produces loyal companions in the style of the great masters. With abundant passion if not a touch of obsession, in my workshop I realize my own dreams and those of my clients.

On the next few pages you can find out more about what I stand for and what makes a bespoke shoe.

Use the arrows in the frame to flick through. On the touchscreens, you can simply swipe to move on.